Solusi

Horse Construction menawarkan rangkaian lengkap material perkuatan struktur dengan dukungan teknis, dukungan dokumentasi, dukungan produk, dukungan perangkat lunak, dukungan proyek.

By Xu Jiang, Cheng Tan(from Horse), Xuhong Qiang, Song Han(from Horse), Andi Shen(from Horse)

This article is jointly released by Tongji University and Shanghai Horse Construction Technology Co., Ltd

Abstract

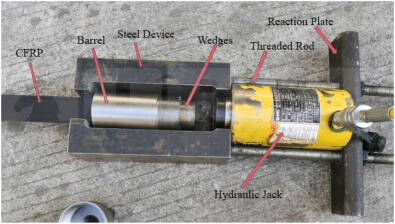

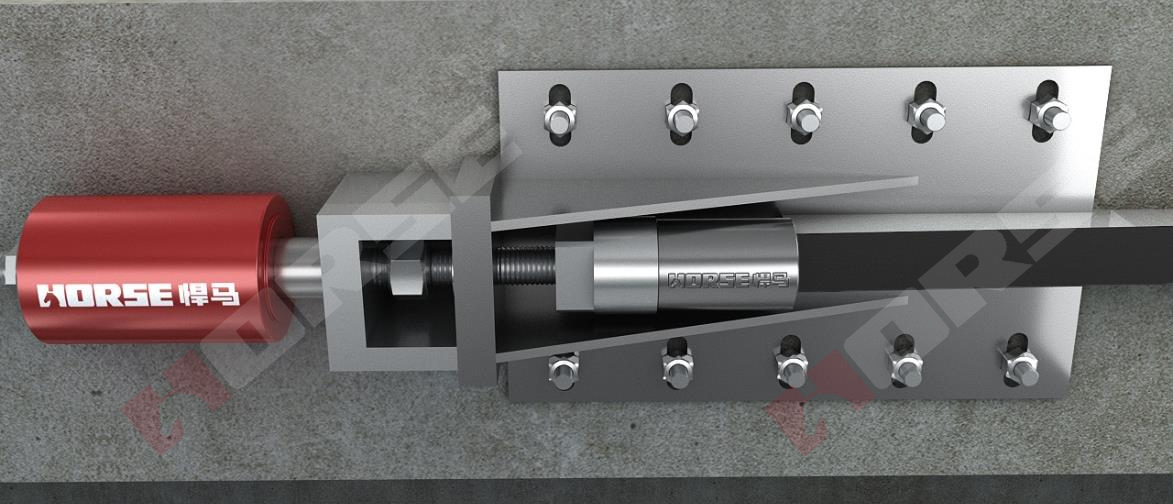

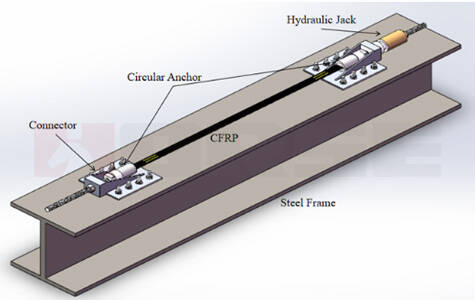

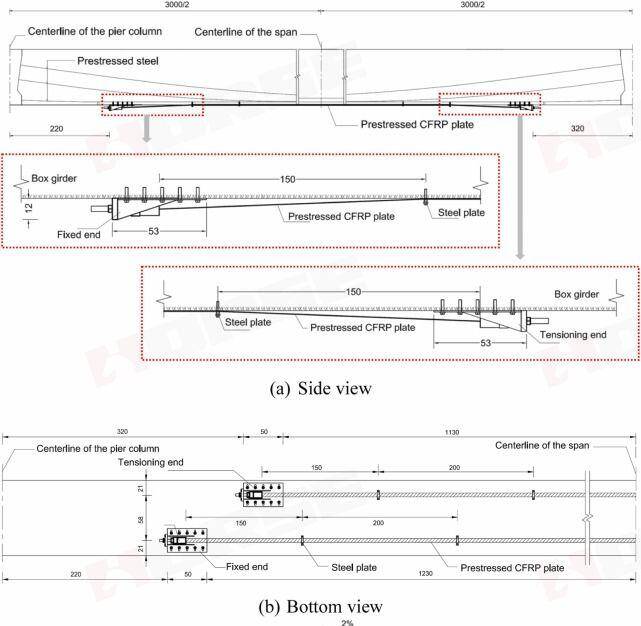

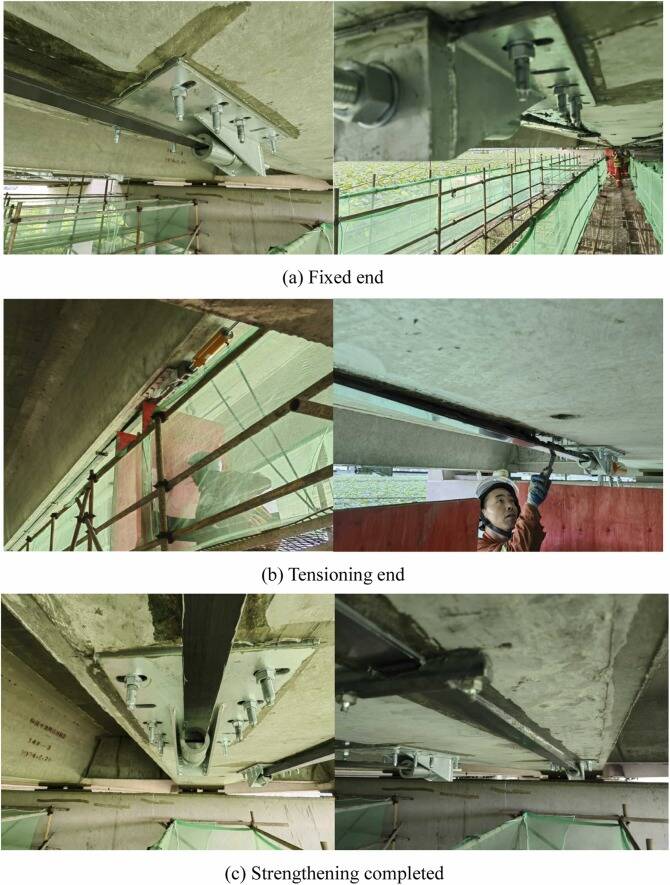

Carbon fiber reinforced polymer (CFRP) has been proved effective in flexural strengthening of reinforced concrete (RC) beams. Various anchor systems have been developed to prevent premature debonding of CFRP plates for structural reinforcement applications. In this study, a novel circular wedged anchor system was proposed and tested under tensile load. The new anchor system includes circular barrel, connector and toothed wedges. Parameters such as intensity and height of tooth, gap between wedges and wedge angle were investigated in order to optimize the proposed anchor system. Effects of above parameters on capacity of the proposed anchor system are presented in the paper. The test results indicate full tensile strength of the tested CFRP plate could be developed using the optimized anchor system. A practical application of the proposed anchor system has been employed in the structural reinforcements of Tongyu River Bridge in China, and this system is found very effective in bridge cracking control via the practical long-term bridge inspections after strengthening.

Circular Anchor System For CFRP Plates

Conclusions

This paper proposed an innovative circular anchor strengthening system for CFRP plates. Experimental tests of 10 anchors with various parameters were conducted to investigate the effects of wedge angle, tooth pattern and gap between the wedges. A case study of Tongyu River Bridge strengthened by the prestressed CFRP plates was presented. The conclusions can be drawn as follows:

•The proposed system is capable of developing 99.6 % tensile strength of 50 * 2 mm CFRP plates, achieving the rupture failure in tests, which is the most desired failure mode.

•Depth of the tooth has evident effect on failure mode and capacity of the anchor system. Deeper tooth tends to cause larger stress on CFRP plates, as a result, splitting failure is more likely to occur.

•The deformation of CFRP and energy absorption of the proposed system is related to the failure mode of CFRP plates. The slipping failure results in a significant reduction of CFRP deformation and energy absorption.

•Spacing of the tooth showed significant effect on performance of the proposed anchor system. Denser distribution of the tooth can improve friction between CFRP and wedges. However, finer tooth would dramatically increase manufacturing costs. For cost concern, 1 mm spacing is suggested in practice.

•Wedge angle has significant effect on failure mode and anchor capacity. Large angle results in a smaller friction, which leads to the slipping failure. Anchors failed in slipping can develop up to 72.1 % of the tested tensile strength of CFRP.

•Smaller gap (25 % of the CFRP thickness) resulted in less contact area between CFRP and wedge, which caused slipping failure. The anchors with gaps larger than 40 % of CFRP thickness exhibited similar performance, and the anchoring efficiency is over 90 %, which is very ideal in the practical application.

•For most of this type of anchors, 220 kN presetting load, which is approximately 85 % of the ultimate capacity of CFRP plates, can effectively prevent sliding of wedges against barrel before the load reaching 200 kN and no apparent damage was observed during presetting.

•The innovative circular anchor system for prestressed CFRP plates has been successfully applied in Tongyu River Bridge in China. The developed strengthening system is proved effective on cracking based on the current long-term inspection results.

Anda dapat menemukan segala yang Anda butuhkan di sini. Percayalah dan cobalah produk - produk ini, Anda akan menemukan perbedaan yang besar setelah itu.

Pelat polimer bertulang serat karbon (CFRP) Horse adalah pelat komposit yang diawetkan terlebih dahulu, yang diikatkan ke struktur sebagai perkuatan eksternal dengan epoksi HM-120CP.

Sistem Laminasi CFRP prategang Kuda (sistem CFRP pasca-tegang) mencakup perangkat penahan dan laminasi serat karbon yang dirancang khusus untuk jembatan, bangunan, dan tulangan struktur baja.

Perekat laminasi serat karbon Horse HM-120CP adalah perekat berbasis epoxy komponen ganda dengan daya rekat yang kuat, daya geser, dan daya anti-penuaan. Ini adalah epoxy yang digunakan untuk merekatkan laminasi serat karbon untuk penguatan struktural.