Solusi

Horse Construction menawarkan rangkaian lengkap material perkuatan struktur dengan dukungan teknis, dukungan dokumentasi, dukungan produk, dukungan perangkat lunak, dukungan proyek.

Advantages and disadvantages of prestressed carbon plate and carbon plate

In bridge reinforcement, there are some advantages and disadvantages between prestressed carbon plates and carbon plates.

Advantage:

Pre -stress effect: Pre -stress carbon plates can be prestressed by applying prestressed stress to effectively improve the bearing capacity and stiffness of the structure. This prestressed effect can reduce the deformation and deflection of the structure and improve the performance of the structure.

High -intensity and stiffness: The prestressed carbon plate uses carbon fiber material, which has high strength and stiffness, which can provide a large reinforcement effect. It can increase the bearing capacity of the bridge and improve the stiffness and stability of the structure.

Durability and corrosion resistance: carbon fiber materials have excellent durability and corrosion resistance. It can resist the erosion of factors such as humidity, chemicals and salt corrosion, thereby extending the life of the bridge.

Construction flexibility and adaptability: prestressed carbon plate reinforcement has high flexibility and adaptability. Carbon fiber materials can be customized according to the geometric shape and component characteristics of the bridge, which is suitable for various bridge structures and component types.

Reinforcement effect: Pre -stress carbon plates can restore or increase the carrying capacity of the original structure to a certain extent by applying prestress. The carbon plate mainly improves the performance of the structure by increasing the stiffness of the bridge. Therefore, prestressed carbon plates may be more significant in reinforcement effects, especially suitable for the structure that needs to increase the bearing capacity.

Disadvantages:

High cost: Compared with traditional reinforced materials, the cost of prestressed carbon board is higher. The manufacturing and processing process of carbon fiber materials is more complicated, resulting in higher prices.

High construction technical requirements: The construction of prestressed carbon boards requires higher technical requirements and construction processes. For construction workers, professional knowledge and experience are required to ensure the reinforcement effect and construction quality.

Reinforcement effect: Pre -stress carbon plates can restore or increase the carrying capacity of the original structure to a certain extent by applying prestress. The carbon plate mainly improves the performance of the structure by increasing the stiffness of the bridge. Therefore, prestressed carbon plates may be more significant in reinforcement effects, especially suitable for the structure that needs to increase the bearing capacity.

Construction difficulty: The construction of prestressed carbon plates is relatively complicated, and steps such as design, component prestressing reinforcement, and tension anchoring need to be designed. The construction of the carbon plate is relatively simple, mainly because it is pasted or fixed on the structure surface. Therefore, the construction of prestressed carbon plates is difficult, and requires higher levels of construction technology and professional knowledge.

For more details of prestressed CFRP plate, please check

https://www.horseen.com/product/prestressed-FRP-System

Anda dapat menemukan segala yang Anda butuhkan di sini. Percayalah dan cobalah produk - produk ini, Anda akan menemukan perbedaan yang besar setelah itu.

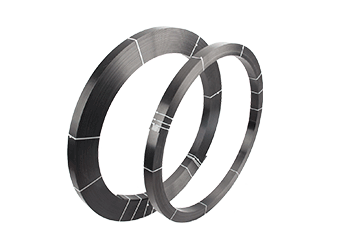

Pelat polimer bertulang serat karbon (CFRP) Horse adalah pelat komposit yang diawetkan terlebih dahulu, yang diikatkan ke struktur sebagai perkuatan eksternal dengan epoksi HM-120CP.

Sistem Laminasi CFRP prategang Kuda (sistem CFRP pasca-tegang) mencakup perangkat penahan dan laminasi serat karbon yang dirancang khusus untuk jembatan, bangunan, dan tulangan struktur baja.

Perekat laminasi serat karbon Horse HM-120CP adalah perekat berbasis epoxy komponen ganda dengan daya rekat yang kuat, daya geser, dan daya anti-penuaan. Ini adalah epoxy yang digunakan untuk merekatkan laminasi serat karbon untuk penguatan struktural.