Solusi

Horse Construction menawarkan rangkaian lengkap material perkuatan struktur dengan dukungan teknis, dukungan dokumentasi, dukungan produk, dukungan perangkat lunak, dukungan proyek.

Case Study On How Prestressed Carbon Fiber Plate Reinforce Concrete Double T Slabs

Engineering background

The concrete double T slabs of a factory that had excessive deflection. The factory building is a single-story frame structure, the beams and columns are cast-in-place frame members, and the slabs are prefabricated prestressed concrete double T slabs. Slab size: 29980mm*2390mm. T-beam bottom width is 110mm, web height: 710-1085mm.

Analysis of current situation and causes of double T slab diseases

On-site diseases:

① There are many cracks on the T beam of the double T slab (the crack spacing within 10 meters of the mid-span is 1m, and the crack spacing within 10 meters of the beam end is 1.5m). The cracks penetrate the bottom slab and extend 30-35cm toward the web. The crack width is 1-2mm wide.

② The double T-slab sinks as a whole, the mid-span deflection of the cracked T-beam is about 30cm, and the mid-span deflection of the uncracked T-beam is about 25cm. (Note: The blue line in Figure 5 is the level stretched from the bottom of the beam at both ends, and the deflection is clearly visible)

Disease cause analysis:

① The actual load of the double T slab is much greater than the design load (the design load is 150kg/m2, the actual load is about 400kg/m2)

② The prestressed steel strand may have excessive prestress loss.

③ The strength of concrete is insufficient. (Concrete that is not dense and pitted is more common)

Reinforcement plan and construction technology

Maintenance and reinforcement plan:

As a prestressed concrete structure, this prefabricated double T slab has many transverse cracks, with a maximum crack width of 2mm and a maximum deflection of 30cm. According to the shape, distribution and development of cracks, the double T slab shows insufficient bearing capacity. In order to improve the durability and safety performance of the double T-slab, the 30m-span T-beam is reinforced with prestressed carbon fiber plates.

① For the 110mm wide T-beam, use a 50mm wide and 3mm thick carbon plate.

② Based on the span of 30m and the distribution of cracks, a 25m-long carbon plate is used.

③ In view of the on-site disease, the tension value of the prestressed carbon plate is designed to be 1000MPa (15t).

Construction technology:

① Set up a steel pipe frame under the double T-slab T beam.

② Drill holes at the anchorage position of the prestressed carbon plate.

③ Installation of prestressed carbon plate anchors.

④ Installation of prestressed carbon fiber plate.

⑤ Prepare glue and apply structural glue.

⑥ Prestressed tensioning.

Anda dapat menemukan segala yang Anda butuhkan di sini. Percayalah dan cobalah produk - produk ini, Anda akan menemukan perbedaan yang besar setelah itu.

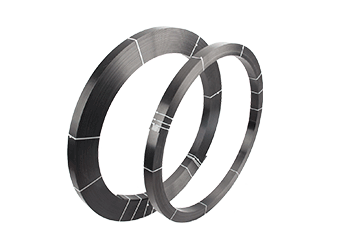

Pelat polimer bertulang serat karbon (CFRP) Horse adalah pelat komposit yang diawetkan terlebih dahulu, yang diikatkan ke struktur sebagai perkuatan eksternal dengan epoksi HM-120CP.

Sistem Laminasi CFRP prategang Kuda (sistem CFRP pasca-tegang) mencakup perangkat penahan dan laminasi serat karbon yang dirancang khusus untuk jembatan, bangunan, dan tulangan struktur baja.

Perekat laminasi serat karbon Horse HM-120CP adalah perekat berbasis epoxy komponen ganda dengan daya rekat yang kuat, daya geser, dan daya anti-penuaan. Ini adalah epoxy yang digunakan untuk merekatkan laminasi serat karbon untuk penguatan struktural.