Solusi

Horse Construction menawarkan rangkaian lengkap material perkuatan struktur dengan dukungan teknis, dukungan dokumentasi, dukungan produk, dukungan perangkat lunak, dukungan proyek.

Uji Lepas Pelat Serat Karbon: Panduan Singkat Menuju Keberhasilan vs. Kegagalan

Penasaran apa yang membuat uji tarik laminasi serat karbon berhasil atau gagal? Berikut perbandingan singkat standar global:

| Standar | Kesuksesan | Kegagalan |

| ACI 440.2R-17 | Kegagalan Kohesif, Pecahnya FRP | Kegagalan Perekat, Kegagalan Campuran |

| ISO 10406-1 | Kegagalan Kohesif, Pecahnya FRP | Kegagalan Perekat, Kegagalan Campuran |

| EN 1542 | Kegagalan Kohesif | Kegagalan Perekat, Kegagalan Campuran |

| ASTM D7522 | Kegagalan Kohesif, Pecahnya FRP | Kegagalan Perekat, Kegagalan Campuran |

| JSCE-E 531 | Kegagalan Kohesif, Pecahnya FRP | Kegagalan Perekat, Kegagalan Campuran |

Poin Utama:

Kegagalan Kohesif

Kegagalan Perekat

Definisi: Kegagalan perekat mengacu pada kegagalan yang terjadi pada antarmuka antara dua material yang terikat. Hal ini terjadi ketika gaya perekat antara kedua material tidak cukup kuat untuk menahan gaya yang diberikan, menyebabkan kedua material terpisah pada garis ikatan. Hal ini dapat disebabkan oleh faktor-faktor seperti persiapan permukaan yang buruk, pemilihan perekat yang tidak tepat, atau tekanan berlebih pada antarmuka.

FRP Rupture

Definisi: FRP rupture adalah mode kegagalan yang spesifik untuk material Polimer Bertulang Serat (FRP). FRP rupture melibatkan putusnya serat dan matriks polimer di sekitarnya dalam komposit FRP. Hal ini terjadi ketika FRP mengalami beban mekanis yang berlebihan, seperti gaya tarik, tekan, atau geser yang tinggi, yang melebihi kemampuan kekuatan material FRP.

Kegagalan Campuran

Definisi: Kegagalan campuran adalah mode kegagalan kompleks yang menggabungkan elemen-elemen dari berbagai mekanisme kegagalan. Kegagalan ini biasanya melibatkan kombinasi kegagalan kohesif dalam satu atau lebih material dan kegagalan adhesif pada antarmuka antar material, atau kombinasi berbagai jenis kegagalan dalam sistem komposit atau multi-material.

Anda dapat menemukan segala yang Anda butuhkan di sini. Percayalah dan cobalah produk - produk ini, Anda akan menemukan perbedaan yang besar setelah itu.

Pelat polimer bertulang serat karbon (CFRP) Horse adalah pelat komposit yang diawetkan terlebih dahulu, yang diikatkan ke struktur sebagai perkuatan eksternal dengan epoksi HM-120CP.

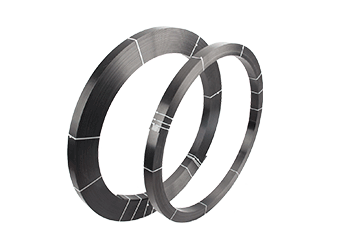

HM-1.4TT adalah strip polimer bertulang serat karbon searah (CFRP) berkekuatan tinggi dan modulus tinggi untuk penguatan struktural

HM-1.4TM adalah laminasi/strip/pelat polimer bertulang serat karbon searah modulus tinggi (CFRP) untuk penguatan struktural