Solusi

Horse Construction menawarkan rangkaian lengkap material perkuatan struktur dengan dukungan teknis, dukungan dokumentasi, dukungan produk, dukungan perangkat lunak, dukungan proyek.

The prestressed CFRP laminate system is different from the prestressed steel strand system. It is a bonded prestressed reinforcement mode. The anchorage only bears the prestressing effect when the tension is completed, and the stress load depends on the connection and transmission between the carbon fiber sheet glue and the target structure.

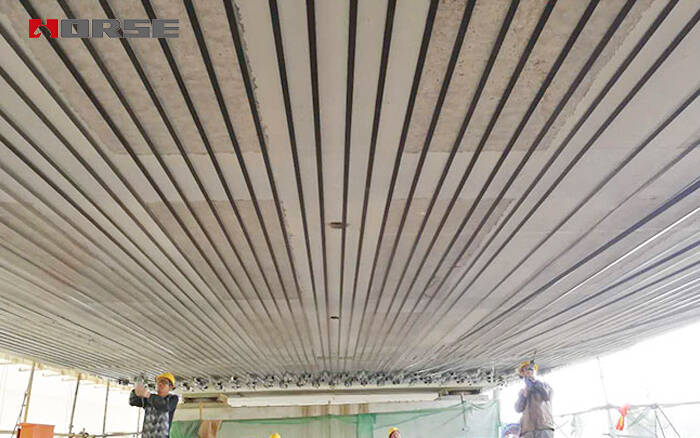

The recent Wuhan Jun Shan bridge project has made Horse Construction's Prestressed CFRP laminate system an unprecedented application and test. At the same time, while concentrating on developing a more stressed and smaller prestress system, Horse Construction also has a profound understanding of the reinforcement design of the prestressed carbon fiber system.

First of all, the prestressed CFRP laminate system is different from the prestressed steel strand system. It is a bonded prestressed reinforcement mode. The anchorage only bears the prestressing effect when the tension is completed, and the stress load depends on the connection and transmission between the carbon fiber sheet glue and the target structure. Therefore, the prestressed carbon fiber system can be regarded as a "high definition" version of carbon fiber reinforced polymer (CFRP) reinforcement. By adjusting the prestress and prestrain value of CFRP, the CFRP plate is forced at the same time as the original member. And when the original component reaches the ultimate state of reinforcement, CFRP laminate can give full play to its tensile strength. At the same time, the cracks and deflection of the original components are controlled within the allowable range.

The design of prestressed CFRP laminate system can be based on two ideas:

Idea one: according to the bending bearing capacity required by the reinforced component, the relative compression zone height in the limit state after reinforcement is calculated, and then the required CFRP section area is obtained through the force balance of the bending section, and the required CFRP specification is selected. Then, the cracks and deflection limits of the strengthened members under design loads are taken as 0.6-0.7 times of the design values of tensile strength. If the numerical value does not meet the prescribed value, it shows that the deformation of the original component is too large, it is appropriate to design according to the idea of crack or deflection control, can adopt the idea 2 to design.

Idea two: according to the deflection and crack limits of the reinforced components, the design is carried out. The main idea is based on the method of degree of prestressing in Chapter 7 of "External Prestressing Reinforcement Technology for Highway Reinforced Concrete Simply Supported Beam Bridges". Prestress is a parameter describing the magnitude of prestress, which is defined as the ratio between the moment of prestressed concrete and the working moment. For different original design load conditions and existing target load conditions, the appropriate prestress degree can be found. Then first, according to the pre stress prediction, the effective prestress (concrete normal stress produced by the prestressing force) is estimated by the prestress of the cross section of the cross section and the lower edge of the cross section. Then the prestressing force of the back tensioning component is the tensile stress value required for the prestressed CFRP. Then the cross-sectional area of CFRP is calculated according to the design value of tensile strength 0.6-0.7 times, and the required CFRP specifications are selected. Finally, check whether the target flexural capacity of the required components meets the requirements, and check the actual crack and deflection values. If the bending capacity of the required members does not meet the requirements, the original member reinforcement should be controlled according to the bearing capacity, can be used to design ideas 1.

The difference between the above two design ideas is only the different methods to predict the area of carbon fiber (predicted by the bearing capacity or according to the crack and deflection), but in fact, the two methods consider the difference in the design form of the original component and the difference in the failure form of the component after the bearing capacity is raised. For example, the section area of the original component is large and the reinforcement ratio is small. In this case, the deflection of the bridge will not exceed the standard due to the sufficient section stiffness, so it is more appropriate to use the bending capacity as the target variable for calculation.

Anda dapat menemukan segala yang Anda butuhkan di sini. Percayalah dan cobalah produk - produk ini, Anda akan menemukan perbedaan yang besar setelah itu.

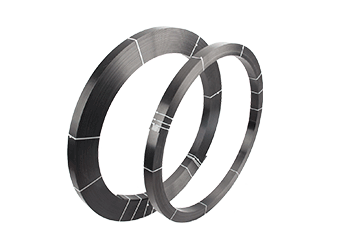

Pelat polimer bertulang serat karbon (CFRP) Horse adalah pelat komposit yang diawetkan terlebih dahulu, yang diikatkan ke struktur sebagai perkuatan eksternal dengan epoksi HM-120CP.

Sistem Laminasi CFRP prategang Kuda (sistem CFRP pasca-tegang) mencakup perangkat penahan dan laminasi serat karbon yang dirancang khusus untuk jembatan, bangunan, dan tulangan struktur baja.

Perekat laminasi serat karbon Horse HM-120CP adalah perekat berbasis epoxy komponen ganda dengan daya rekat yang kuat, daya geser, dan daya anti-penuaan. Ini adalah epoxy yang digunakan untuk merekatkan laminasi serat karbon untuk penguatan struktural.