Solusi

Horse Construction menawarkan rangkaian lengkap material perkuatan struktur dengan dukungan teknis, dukungan dokumentasi, dukungan produk, dukungan perangkat lunak, dukungan proyek.

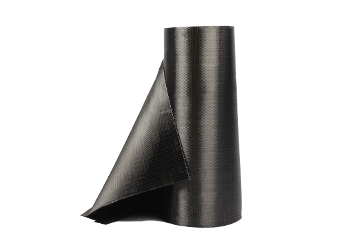

The carbon fiber fabric(CFRP) reinforcement and repairing concrete structure is a newly developed reinforcement technology in recent years. It has many advantages such as simple construction, strong adaptability and chemical corrosion resistance. It has been applied in bridge engineering.

With the extension of the service life, many of the concrete bridges built in China in the 1980s have experienced engineering quality problems. Especially in the coastal areas, the bridge structure, due to years of sea breeze and wet erosion, combined with the use of salt, causing corrosion damage is more serious. There are phenomena such as concrete cracking, spalling, steel corrosion, etc., and even the bridge loses the original bearing capacity, so it is urgent to repair and strengthen the old bridge.

The carbon fiber fabric(CFRP) reinforcement and repairing concrete structure is a newly developed reinforcement technology in recent years. It has many advantages such as simple construction, strong adaptability and chemical corrosion resistance. It has been applied in bridge engineering.

The reinforcement of the bridge structure by carbon fiber fabric can be divided into three parts: crack treatment, repair of the falling part and reinforcement of the T-span mid-span.

(1) Crack treatment: For the crack caused by force, carry out structural check calculation design, and affix 1~2 layers of carbon cloth for reinforcement.

(2) Repair of the falling part: Except for the accidental concrete falling defect part in the T-beam span, the epoxy mortar is higher than the original bridge concrete strength grade, and it is restored to the original shape, and then bonded with carbon cloth.

(3) T-beam mid-span reinforcement: This is the part that needs to be strengthened. Where the concrete of the T-beam span has been cracked or peeled off, the exposed bare steel is rusted and the concrete is removed from the cracked part. Until the main part of the concrete, the exposed rusted steel bars are derusted, then repaired with high-strength grade epoxy mortar, and finally reinforced with two layers of carbon cloth at the bottom of the web to improve the bending capacity.

Anda dapat menemukan segala yang Anda butuhkan di sini. Percayalah dan cobalah produk - produk ini, Anda akan menemukan perbedaan yang besar setelah itu.

Viskositas rendah, impregnasi yang baik, dengan sifat tiksotropik tertentu, digunakan untuk impregnasi dan pasta permukaan komponen yang diperkuat dan produk serat. Peran perekat serat karbon Horse adalah untuk sepenuhnya meresap ke dalam produk serat, dan

Sistem Laminasi CFRP prategang Kuda (sistem CFRP pasca-tegang) mencakup perangkat penahan dan laminasi serat karbon yang dirancang khusus untuk jembatan, bangunan, dan tulangan struktur baja.

Serat karbon Horse Construction digunakan untuk perkuatan struktural, perbaikan, dan perbaikan substrat beton, pasangan bata, baja, dan kayu pada bangunan, jembatan, jalan raya, rel kereta api, terowongan, dermaga, dan bandara sipil.