Solusi

Horse Construction menawarkan rangkaian lengkap material perkuatan struktur dengan dukungan teknis, dukungan dokumentasi, dukungan produk, dukungan perangkat lunak, dukungan proyek.

First of all, the quality of carbon fiber fabric itself is very important. If the quality of carbon cloth and the structural gum used with it is not up to standard, especially when the inferior carbon cloth is purchased, the tension is uneven during weaving, causing bubbles.

Bubble formation after FRP reinforcementis often encountered in engineering, so Horse Construction to sum up for you, how to deal with this situation.

First of all, the quality of carbon fiber fabric itself is very important. If the quality of carbon cloth and the structural gum used with it is not up to standard, especially when the inferior carbon cloth is purchased, the tension is uneven during weaving, causing bubbles.

Secondly, it is one of the most common problems in engineering: the ground treatment of concrete structure foundation is not good enough. The concrete surface must be cleaned up. If the steel bars are exposed, the corroded parts of the steel bars surface need to be cleaned up. Then the mending glue is leveled and repaired with Mancatel. After the mending glue is dried, the next step can be taken.

The concrete pasted with carbon fibers should be kept dry, and the water content of the surface should not be more than 4% and not more than 6%. The concrete with excessive water content should be manually dried or pasted with moisture-resistant carbon fibers structural adhesives. Then, when pasting, we must use matching structural adhesives to infiltrate into the voids between carbon fiber monofilaments as far as possible, so as to improve the performance of working together between the monofilaments.

Press the reinforcing part with hand or tool to ensure that there is no big gap and then compact it evenly and smoothly with rubber drum along the direction of the fiber, so that the structural glue overflows from both sides, ensuring that there is no void between the carbon cloth and the structure.

Anda dapat menemukan segala yang Anda butuhkan di sini. Percayalah dan cobalah produk - produk ini, Anda akan menemukan perbedaan yang besar setelah itu.

Viskositas rendah, impregnasi yang baik, dengan sifat tiksotropik tertentu, digunakan untuk impregnasi dan pasta permukaan komponen yang diperkuat dan produk serat. Peran perekat serat karbon Horse adalah untuk sepenuhnya meresap ke dalam produk serat, dan

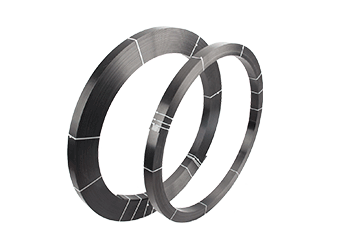

Pelat polimer bertulang serat karbon (CFRP) Horse adalah pelat komposit yang diawetkan terlebih dahulu, yang diikatkan ke struktur sebagai perkuatan eksternal dengan epoksi HM-120CP.

Serat karbon Horse Construction digunakan untuk perkuatan struktural, perbaikan, dan perbaikan substrat beton, pasangan bata, baja, dan kayu pada bangunan, jembatan, jalan raya, rel kereta api, terowongan, dermaga, dan bandara sipil.