Solusi

Horse Construction menawarkan rangkaian lengkap material perkuatan struktur dengan dukungan teknis, dukungan dokumentasi, dukungan produk, dukungan perangkat lunak, dukungan proyek.

Different structural reinforcement effects in different orders in carbon fiber plate reinforcement and section enlarge

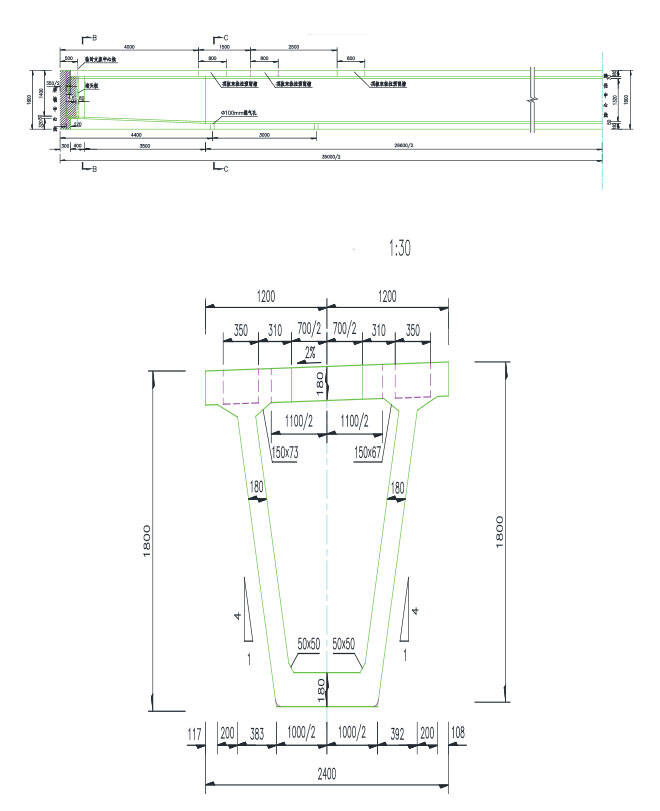

This paper takes a prestressed concrete simply supported box girder bridge in Guizhou Province as the background. The length of the bridge is 35m, the calculated span is 34m, and the design load is Class II highway.

In order to improve the load-bearing capacity of the bridge, it is proposed to adopt a joint reinforcement method of sticking 2mm carbon fiber plate on the bottom surface of the beam and removing and replacing the original 11.5cm second-stage pavement of the bridge deck to strengthen the simply supported beam. In the process of joint reinforcement of the bridge, the reinforcement effect is analyzed by replacing the carbon fiber plate and the laminated layer in the different reinforcement sequence.

Using the finite element analysis software MIDAS/FEA, aiming at the existing reinforcement methods, a beam bridge model with different reinforcement sequences was established. Reinforcement method: enlarged section, carbon fiber plate and prestressed carbon fiber plate, etc. Through the comparative analysis of the beam bridge under different reinforcement sequence model force deformation and crack expansion.

The results show that the order of strengthening the carbon fiber plate first and then increasing the cross-section is better than increasing the cross-section first and then strengthening the carbon fiber plate and simultaneously increasing the cross-section and strengthening the carbon fiber plate. In actual engineering, when the reinforcement work surfaces of the two reinforcement methods do not conflict, the order of the reinforcement methods may not be considered. The use of two reinforcement methods for simultaneous construction can save construction time while hardly affecting the reinforcement effect.

The beam bridge adopts different reinforcement sequences in the joint reinforcement, which slightly improves the cracking moment of the beam bridge, the yield moment of the steel bar, and the structural rigidity. However, the ductility of the beam bridge and the maximum width of the crack are slightly reduced, and it has almost no effect on the crack propagation along the longitudinal direction and the height of the beam, and has no effect on the ultimate bending moment of the beam bridge.

Anda dapat menemukan segala yang Anda butuhkan di sini. Percayalah dan cobalah produk - produk ini, Anda akan menemukan perbedaan yang besar setelah itu.

Pelat polimer bertulang serat karbon (CFRP) Horse adalah pelat komposit yang diawetkan terlebih dahulu, yang diikatkan ke struktur sebagai perkuatan eksternal dengan epoksi HM-120CP.

Perekat pengikat pelat baja struktural HM-120 adalah produk epoksi dua komponen, dengan daya rekat kuat, pengerasan pada suhu ruangan. Produk ini memiliki sifat anti-penuaan dan ketahanan guncangan yang sangat baik dalam daya rekat sendiri dan daya rekat t

Epoxy penahan injeksi Horse HM-500 adalah bahan penahan tiksotropik berbasis resin epoksi 2 komponen berkinerja tinggi untuk batang dan tulangan, cocok untuk digunakan pada beton kering dan basah.