Solusi

Horse Construction menawarkan rangkaian lengkap material perkuatan struktur dengan dukungan teknis, dukungan dokumentasi, dukungan produk, dukungan perangkat lunak, dukungan proyek.

carbon fiber reinforced polymer(CFRP) plate for concrete repair and structural strengthening

Carbon fiber plate is a composite material pultruded with carbon fiber and resin, which inherits the characteristics of light weight, high lightness and corrosion resistance of carbon fiber. The matching special resin for carbon fiber plate (carbon plate glue) is mainly used in the reinforcement of carbon fiber plate. It has good adhesion, no flow, and strong penetration. The carbon fiber plate reinforcement system is similar to the carbon fiber cloth used in bending and seismic reinforcement of concrete structures.

The advantages of carbon fiber plate for structural reinforcement

1. High tensile strength

The tensile strength is several times that of ordinary steel, and the elastic toughness is also better than that of ordinary steel, which is mainly due to its physical and mechanical properties.

2. High temperature and corrosion resistance

Both carbon fiber filament and resin can withstand high temperature corrosion, so it can be used normally in acid, alkali, salt, etc. and bad weather, and it will also protect the internal structure.

3. Light weight and good toughness

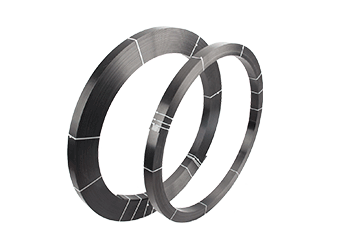

The weight of carbon fiber plate is very light, only one-fifth of steel, but its strength is several times that of steel, and it can also be coiled, which is convenient for transportation of larger lengths.

4. Easy to use

There is no need for large-scale construction equipment and professional equipment during use. The use of carbon fiber plate is arbitrary because it can be easily cut at will, the construction is simple, and the construction period is short.

Construction process of carbon fiber plate for structural reinforcement

① The carbon fiber plate should be cut according to the size required by the design, and the bonding resin should be prepared according to the process regulations provided by the product supplier;

②Wipe the surface of the carbon fiber plate clean to no dust. When two layers need to be pasted, both sides of the bottom carbon fiber plate should be wiped clean;

③ The cleaned carbon fiber plate should be coated with bonding resin immediately, the glue layer should be protruding, and the average thickness should not be less than 2mm;

④ Press lightly the carbon fiber plate coated with bonding resin to the position to be pasted by hand. Use a rubber roller to compact evenly and smoothly along the fiber direction, so that the resin overflows from both sides to ensure compactness and no voids. When multiple carbon fiber plates are pasted in parallel, the gap between the two plates should not be less than 5mm;

⑤ When two layers of carbon fiber plates need to be pasted, they should be pasted continuously. If it cannot be pasted immediately, clean the bottom carbon fiber plate before starting to paste it again.

Why choose pre-stressed carbon plates to strengthen large-span structures?

1. The anchorage channel and clip adopt reasonable inclination angle, tooth pattern angle, tooth pattern depth and tooth pattern extension to the length of the clip to make the contact between the clip and the carbon fiber plate closer and firmer. It overcomes the common problems of sliding and splitting of carbon fiber plates during tensioning.

2. The anchor frame adopts a one-piece stamping forming process, which has high overall strength and avoids insufficient strength caused by welding and uneven stress distribution in the welding seam.

3. The anchor block channel and clip adopt high-precision wire cutting technology, and the error is controlled within 0.1mm. The actual force condition and the theoretical analysis have a high degree of fit to ensure the tension effect.

4. The clip and the anchor block are formed by integral cutting, and the numbers of the anchor block and the clip are one-to-one correspondence, to achieve a better fit and adaptability of the contact surface between the anchor block and the clip, and to ensure uniform force.

5. With split design, each part is packaged and transported separately, which is easy to replace.

Anda dapat menemukan segala yang Anda butuhkan di sini. Percayalah dan cobalah produk - produk ini, Anda akan menemukan perbedaan yang besar setelah itu.

Pelat polimer bertulang serat karbon (CFRP) Horse adalah pelat komposit yang diawetkan terlebih dahulu, yang diikatkan ke struktur sebagai perkuatan eksternal dengan epoksi HM-120CP.

Sistem Laminasi CFRP prategang Kuda (sistem CFRP pasca-tegang) mencakup perangkat penahan dan laminasi serat karbon yang dirancang khusus untuk jembatan, bangunan, dan tulangan struktur baja.

Perekat laminasi serat karbon Horse HM-120CP adalah perekat berbasis epoxy komponen ganda dengan daya rekat yang kuat, daya geser, dan daya anti-penuaan. Ini adalah epoxy yang digunakan untuk merekatkan laminasi serat karbon untuk penguatan struktural.