Solusi

Horse Construction menawarkan rangkaian lengkap material perkuatan struktur dengan dukungan teknis, dukungan dokumentasi, dukungan produk, dukungan perangkat lunak, dukungan proyek.

In recent years, carbon wrap solutions have emerged as a groundbreaking technology in the field of structural repair and reinforcement.

In recent years, carbon wrap solutions have emerged as a groundbreaking technology in the field of structural repair and reinforcement. This article explores what carbon wrap solutions are, why they are superior to other methods, their benefits and applications, the process of implementation, problems they can solve, and the advantages they offer.

What are Carbon Wrap Solutions?

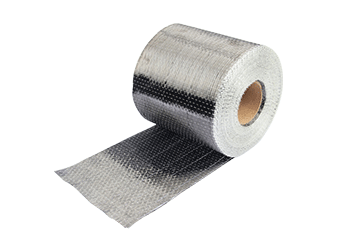

Carbon wrap solutions, also known as carbon fiber reinforced polymer (CFRP) systems, involve the application of carbon fiber sheets or fabrics to enhance the strength and durability of structures. These wraps are lightweight, flexible, and possess excellent tensile strength.

Why are Carbon Wrap Solutions Better Than Others?

a. Superior Strength: Carbon wrap solutions offer exceptional tensile strength, surpassing traditional repair methods such as steel plates or concrete injections. They can withstand high levels of stress and prevent further structural damage.

b. Flexibility: Unlike rigid alternatives, carbon wrap solutions provide flexibility, allowing them to conform to various shapes and sizes of structures. This ensures effective reinforcement in challenging areas, such as curved or irregular surfaces.

c. Corrosion Resistance: Carbon fiber materials are highly resistant to corrosion, making them ideal for applications in corrosive environments. Unlike steel reinforcements, carbon wraps do not deteriorate over time, resulting in longer-lasting repairs.

d. Lightweight: Carbon wraps are significantly lighter than traditional alternatives, reducing the additional load on the structure. This feature is particularly advantageous for retrofitting applications, where weight considerations are crucial.

Benefits of Carbon Wrap Solutions:

a. Rapid Installation: Carbon wrap solutions can be applied quickly, minimizing downtime and disruption to the structure. This efficiency is especially beneficial in time-sensitive repair projects.

b. Cost-Effectiveness: Although carbon wrap solutions may have higher upfront costs, they offer long-term cost savings. Their durability and extended lifespan reduce the need for frequent repairs or replacements, resulting in overall cost reduction.

c. Non-Intrusive: Unlike invasive repair methods that may require extensive demolition or excavation, carbon wrap solutions are non-intrusive. They can be applied externally to the structure, minimizing disruption to occupants and preserving the aesthetics of the building.

Applications of Carbon Wrap Solutions:

a. Structural Rehabilitation: Carbon wraps are commonly used to rehabilitate damaged or weakened structures, such as bridges, columns, beams, and walls. They provide an effective solution for restoring load-carrying capacity and structural integrity.

b. Seismic Upgrades: Carbon wrap solutions can enhance the seismic resistance of structures by increasing their ductility and stiffness. This helps mitigate the risk of structural failure during earthquakes and improves overall safety.

c. Retrofitting: Existing structures can benefit from carbon wrap solutions for retrofitting purposes. They can strengthen buildings to meet updated building codes or accommodate changes in use, ensuring compliance and safety.

Including:

Slabs

Piers

Timber Piles

Docks

Dams

Bridges

Beams

Commercial piping

Shaft foundations

Pile foundations

Seawalls

Cement columns

Pen Stocks

Water Intake and Discharge Systems

Problems Carbon Wrap Solutions Can Solve:

a. Structural Degradation: Carbon wrap solutions address issues related to structural degradation, such as corrosion, concrete spalling, fatigue, and delamination.

b. Load-Bearing Capacity: By increasing the load-bearing capacity of structures, carbon wrap solutions can prevent or repair structural failures caused by excessive loads or aging.

c. Structural Resilience: Carbon wraps improve the resilience of structures against environmental factors, such as earthquakes, high winds, or impact events.

Anda dapat menemukan segala yang Anda butuhkan di sini. Percayalah dan cobalah produk - produk ini, Anda akan menemukan perbedaan yang besar setelah itu.

Lembaran serat karbon Horse Construction digunakan untuk perkuatan struktural, perbaikan, dan perbaikan substrat beton, pasangan bata, baja, dan kayu pada bangunan, jembatan, jalan raya, rel kereta api, terowongan, dermaga, dan bandara sipil.

Viskositas rendah, impregnasi yang baik, dengan sifat tiksotropik tertentu, digunakan untuk impregnasi dan pasta permukaan komponen yang diperkuat dan produk serat. Peran perekat serat karbon Horse adalah untuk sepenuhnya meresap ke dalam produk serat, dan

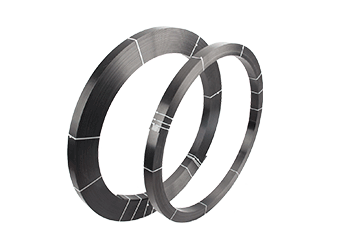

Pelat polimer bertulang serat karbon (CFRP) Horse adalah pelat komposit yang diawetkan terlebih dahulu, yang diikatkan ke struktur sebagai perkuatan eksternal dengan epoksi HM-120CP.