Solusi

Horse Construction menawarkan rangkaian lengkap material perkuatan struktur dengan dukungan teknis, dukungan dokumentasi, dukungan produk, dukungan perangkat lunak, dukungan proyek.

Why The Columns have Cracks? How To Reinforce And Repair Cracks In Concrete Columns?

The reason for the cracking of the columns

1. Excessive load

The load borne by the column exceeds its designed bearing capacity, which may lead to cracking.

2. Foundation settlement

Uneven foundation settlement can cause additional stress on columns, leading to cracking.

3. Quality issues with concrete

Improper mix proportions, inadequate pouring, and poor curing of concrete can all lead to cracking of columns.

4. Corrosion of steel bars

Corrosion of steel bars can cause their volume to expand, resulting in concrete cracking.

5. Temperature changes

The drastic change in temperature may cause thermal expansion and contraction of column concrete, leading to cracking.

6. Earthquake or other external forces

Earthquakes, wind and other external forces may cause damage to columns, leading to cracking.

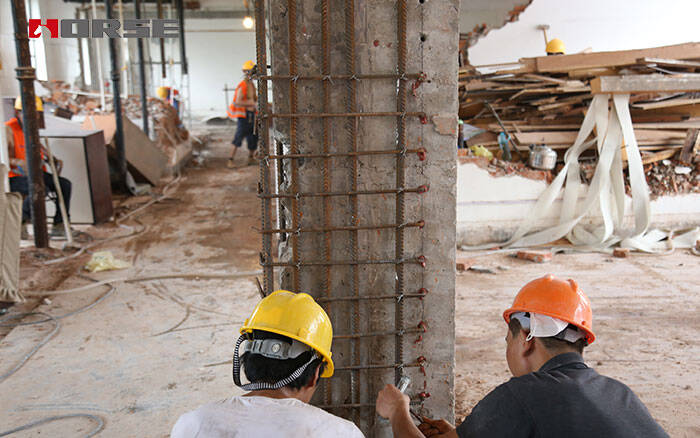

The common causes of column cracking mentioned above have been identified by the building safety appraisal unit to determine the reasons for column cracking in the factory building, the extent of damage, and whether reinforcement measures are needed.

According to the evaluation of the degree of cracking in the column, one or more of the following reinforcement methods can be used for reinforcement treatment:

Enlarged section reinforcement method

principle

By adding load-bearing steel bars and concrete outside the original component section, the new and old load-bearing steel bars and concrete work together to increase the cross-sectional size of the component and improve its load-bearing capacity.

Applicable scope

Suitable for reinforcing reinforced concrete bending and compression members

Advantages and disadvantages

This method has good reinforcement effect, economy, and wide applicability. But the construction is complex, the workload of wet work is large, and the construction period is long, which will have a certain impact on the clearance and aesthetics of the house.

Steel jacketing reinforcement method

principle

By using latex cement or epoxy resin chemical grouting to paste angle steel at the four corners of the component, the original component load is shared by the angle steel, and the angle steel hoop exerts lateral restraint on the core concrete, improving the load-bearing capacity of the component.

Applicable scope

Suitable for the reinforcement of reinforced concrete columns and beams that require significant improvement in cross-sectional bearing capacity and seismic resistance

Advantages and disadvantages

This method is reliable in terms of force, easy to construct, short in duration, and has minimal impact on the usage space. But the steel consumption is relatively high, and the exposed steel parts should be effectively treated with anti-corrosion and fireproof measures

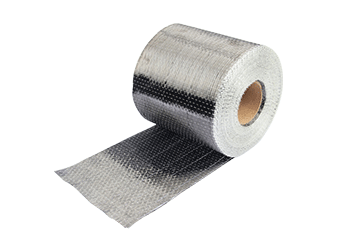

Externally bonded carbon fiber reinforcement method

principle

Fiber composite materials have good tensile strength. By utilizing this property, they can be pasted onto the surface of reinforced concrete components to work together with concrete and improve the load-bearing capacity of the components.

Applicable scope

Suitable for reinforcing reinforced concrete members subjected to bending, large eccentric compression, and tension; Not applicable to plain concrete components, including those reinforced with longitudinal steel bars with a reinforcement ratio of less than 0.2% on one side.

Advantages and disadvantages

This method uses lightweight and high-strength materials, is easy to construct, and has a wide range of applications. For environments with high temperature, high humidity, harmful media, fire prevention requirements, and outdoor conditions directly exposed to sunlight, special adhesives should be used and special protective measures should be taken

Anda dapat menemukan segala yang Anda butuhkan di sini. Percayalah dan cobalah produk - produk ini, Anda akan menemukan perbedaan yang besar setelah itu.

Lembaran serat karbon Horse Construction digunakan untuk perkuatan struktural, perbaikan, dan perbaikan substrat beton, pasangan bata, baja, dan kayu pada bangunan, jembatan, jalan raya, rel kereta api, terowongan, dermaga, dan bandara sipil.

Perekat pengikat pelat baja struktural HM-120 adalah produk epoksi dua komponen, dengan daya rekat kuat, pengerasan pada suhu ruangan. Produk ini memiliki sifat anti-penuaan dan ketahanan guncangan yang sangat baik dalam daya rekat sendiri dan daya rekat t

Perekat pelapisan pelat baja HM-120M adalah perekat perfusi struktural bangunan resin epoksi termodifikasi tipe baru, khususnya untuk mendukung tulangan batang yang terikat perekat. Perekat ini dapat diikat dengan berbagai substrat dan logam, dengan keungg