Solusi

Horse Construction menawarkan rangkaian lengkap material perkuatan struktur dengan dukungan teknis, dukungan dokumentasi, dukungan produk, dukungan perangkat lunak, dukungan proyek.

unidirectional carbon fiber cloth to strengthen the bridge

In recent years, unidirectional carbon fiber cloth has been vigorously promoted and applied in bridge structures, and carbon fiber reinforcement has become an emerging reinforcement technology. The process and requirements of carbon fiber reinforcement are discussed in detail below.

Ensure material homogeneity

The carbon fiber bundles should be evenly distributed and arranged to ensure that the processed carbon fiber cloth is uniformly stressed. If the material of the carbon fiber bundles is not uniform, it is easy to cause uneven forces on the carbon fiber layout after the member is reinforced, and the carbon fiber reinforcement effect cannot be exerted.

The content of prepreg resin in unidirectional carbon fiber cloth

As a structural reinforcement material, carbon fiber cloth contains a certain amount of prepreg resin. The role of the resin is to ensure that the fibers can be restrained and bonded to each other to form a common force. However, if the resin content in the carbon fiber cloth is too high and the impregnation is too thick, the reinforcement and reinforcement effect of the carbon fiber cloth will be reduced. As carbon fiber cloth reinforces the bridge structure, it mainly relies on the upper and lower coating of epoxy resin to repeatedly infiltrate the carbon fiber to exert its reinforcement function. If the amount of resin used is too much, it will easily affect the resin penetration effect when the carbon fiber cloth is pasted, thereby affecting the construction quality.

Control the breaking rate of carbon fiber

Because the fiber filaments in the carbon fiber cloth are very thin, it is prone to breakage. Therefore, during construction, the breaking rate of the fiber filaments should be controlled as much as possible to ensure the continuity and integrity of the fiber sheets. This is also the focus of ensuring the reinforcement effect of the bridge structure. ·

Substrate treatment

According to the design requirements, the structural range that needs to be reinforced is processed. The substrate treatment mainly includes the following steps.

1) Repair the defective part

First of all, it is necessary to remove the broken parts, damaged parts and carbonized layers of the concrete to ensure that the structure is intact. Check and deal with the corrosion of the exposed steel bars, repair the exposed parts and restore them to their original integrity.

2) Crack repair

If there are cracks in the structure, the cracks need to be repaired first. If the crack width is less than 0.2mm, epoxy resin coating can be used for sealing. When the width of the crack is more than 0.2mm, it is necessary to use epoxy resin for grouting.

3) Polishing

The protruding part of the structure surface needs to be polished with a grinder to ensure that the repaired structure surface is as smooth as possible. In addition, it is necessary to use a grinder to grind the corners and corners into rounded corners with a radius of not less than 30mm.

4) Cleaning

Clean the polished surface of the component and dry it sufficiently.

Applying primer

When painting the primer, the main agent and curing agent of the primer should be fully stirred in a certain ratio. The dosage of each agent must be accurate, the mixing must be even, and the adjusted amount each time should be used up within the use time limit. Use a roller brush to evenly apply the primer. After the primer is cured, if there are any protruding parts on the surface, it should be smoothed with sandpaper. When the temperature is below 5°C, the relative humidity is higher than 85%, and the moisture content of the concrete surface is greater than 8%, if there is a possibility of condensation, necessary protective measures must be taken, otherwise the construction cannot be continued.

Structural surface crack repair

For the recessed parts of the surface, epoxy putty can be used to fill it up to restore the surface to a smooth state; for inner corners, segment differences or arched parts, epoxy putty should be used to fill and smooth.

Bonding unidirectional carbon fiber cloth on bridge

In order to prevent damage to the fiber cloth, bends should be avoided as much as possible when the unidirectional carbon fiber cloth is transported, stored, cut or pasted. Before pasting construction, it is necessary to use a steel ruler and wallpaper knife to cut the unidirectional carbon fiber cloth. The cutting must be carried out in strict accordance with the required size. Except for special requirements, usually the length of each section should be within 3m. Configure and stir the glue material according to the requirements, and then use a roller brush to evenly apply it to the parts that need to be pasted, and apply more on the overlap and corners. Special rollers are used to repeatedly roll on the surface of the unidirectional carbon fiber cloth in the same direction until the surface of the carbon fiber cloth is infiltrated with rubber and ensure that the rubber is fully infiltrated into the unidirectional carbon fiber cloth. The surface of the outermost carbon fiber cloth needs to be coated with a layer of rubber. The lap joint of carbon fiber must be above 10cm, and no lap joint is needed in the horizontal direction. After the construction is completed, the unidirectional carbon fiber cloth needs to undergo natural curing for 24 hours to make it reach the initial state of curing. During the 24 hours of natural curing, the cured parts cannot be disturbed. It is also necessary to use 1:2 cement mortar to wipe the surface of the reinforced carbon fiber surface.

Conclusion

The reinforcement of in-service bridges is an important part of bridge engineering. For a large number of bridges with hidden quality and safety hazards, if they are demolished and reconstructed, it will not only cost a lot of money, but also cause long-term traffic interruption. If effective reinforcement and maintenance measures can be taken to restore and improve their carrying capacity, eliminate hidden quality hazards, and enable them to continue their service, it will bring huge social and economic benefits. Therefore, we should attach great importance to the management of existing railway bridges and increase capital investment to keep them in good working condition and ensure the safety of railway transportation.

Anda dapat menemukan segala yang Anda butuhkan di sini. Percayalah dan cobalah produk - produk ini, Anda akan menemukan perbedaan yang besar setelah itu.

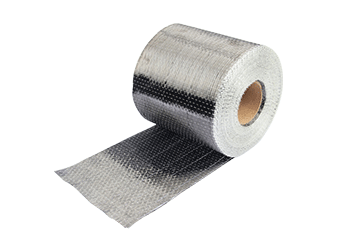

Lembaran serat karbon Horse Construction digunakan untuk perkuatan struktural, perbaikan, dan perbaikan substrat beton, pasangan bata, baja, dan kayu pada bangunan, jembatan, jalan raya, rel kereta api, terowongan, dermaga, dan bandara sipil.

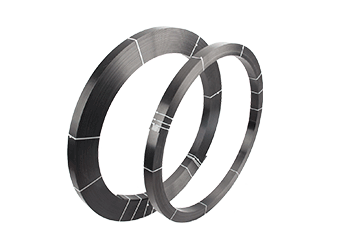

Pelat polimer bertulang serat karbon (CFRP) Horse adalah pelat komposit yang diawetkan terlebih dahulu, yang diikatkan ke struktur sebagai perkuatan eksternal dengan epoksi HM-120CP.

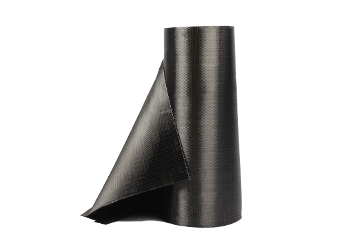

Serat karbon Horse Construction digunakan untuk perkuatan struktural, perbaikan, dan perbaikan substrat beton, pasangan bata, baja, dan kayu pada bangunan, jembatan, jalan raya, rel kereta api, terowongan, dermaga, dan bandara sipil.