Solusi

Horse Construction menawarkan rangkaian lengkap material perkuatan struktur dengan dukungan teknis, dukungan dokumentasi, dukungan produk, dukungan perangkat lunak, dukungan proyek.

Residual fatigue life of carbon fiber laminate reinforced steel structure

Fracture mechanics, as a discipline that only gradually developed in the 1970s, although it appeared relatively late, because it is closely related to the safety of actual materials and structures, its theory has made considerable progress. Fracture mechanics can be divided into fracture statics and fracture dynamics. Among them, the theory of fracture dynamics is not perfect due to its late appearance. In fracture statics, it is divided into linear elastic fracture mechanics and elastoplastic fracture mechanics. When analyzing linear elastic materials, the research method of linear elastic fracture mechanics is not only simple and easy, but also has high precision. Therefore, based on the linear elastic fracture mechanics in fracture statics, this paper studies the high-cycle fatigue remaining life of steel structures reinforced with prestressed CFRP plates.

As the structure is in use, the load it bears changes periodically or non-periodically with time. This changing load on the structure is called an alternating load. Nowadays, many mechanical equipments are working normally under such alternating load. The behavioral process of fatigue failure is relatively cumbersome. According to its development process, fatigue can be roughly divided into the following three steps:

①The crack appearance stage;

②The stage of smooth crack expansion;

③The instability expands to the destruction stage.

This paper studies the remaining life under high-cycle fatigue, ignoring the third stage of rapid crack expansion, the life expression of the first two stages can be obtained: total life of structural reinforcement material = initial number of cycles before reinforcement + remaining fatigue life.

Sum

1) The fatigue life of steel beams strengthened by CFRP plates increases significantly, and the smaller the stress amplitude, the greater the increase in fatigue life.

2) In most of the comparison between the calculated fatigue life and the test fatigue life, it is found that the calculated value is smaller than the test value. This is because in the calculation process, the initial micro cracks of 1 mm inside the steel beam are used for calculation, so the life will be slightly less than the experimental value.

Anda dapat menemukan segala yang Anda butuhkan di sini. Percayalah dan cobalah produk - produk ini, Anda akan menemukan perbedaan yang besar setelah itu.

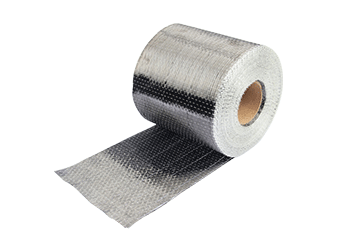

Lembaran serat karbon Horse Construction digunakan untuk perkuatan struktural, perbaikan, dan perbaikan substrat beton, pasangan bata, baja, dan kayu pada bangunan, jembatan, jalan raya, rel kereta api, terowongan, dermaga, dan bandara sipil.

Pelat polimer bertulang serat karbon (CFRP) Horse adalah pelat komposit yang diawetkan terlebih dahulu, yang diikatkan ke struktur sebagai perkuatan eksternal dengan epoksi HM-120CP.

Sistem Laminasi CFRP prategang Kuda (sistem CFRP pasca-tegang) mencakup perangkat penahan dan laminasi serat karbon yang dirancang khusus untuk jembatan, bangunan, dan tulangan struktur baja.